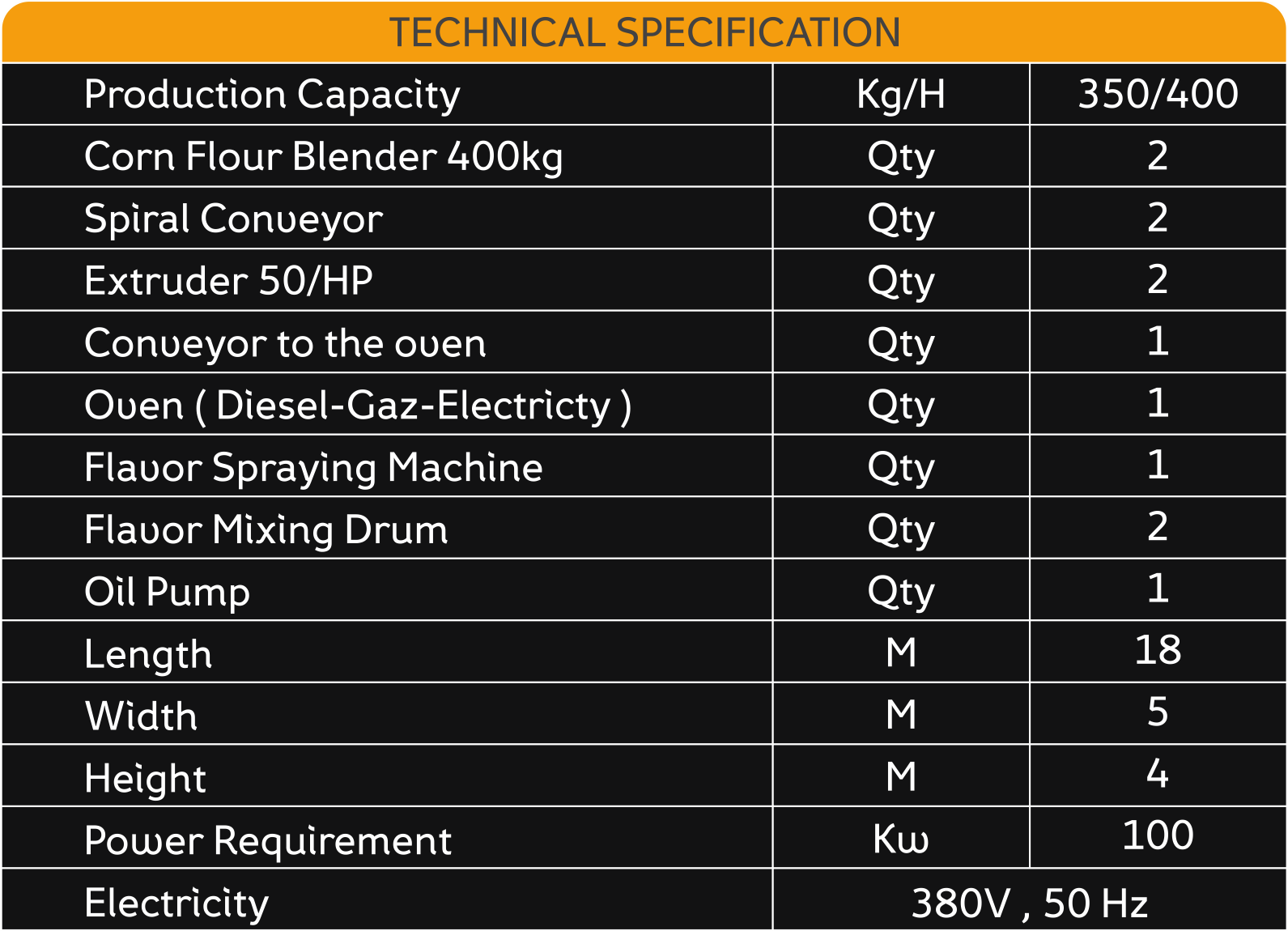

Production capacity 350 – 400 kg per hour

Made of food stainless steel 304

Line sections

Corn Blender, x2

Function: mixing and moisturizing the corn

2 Spiral Conveyors

Function: transferring materials through screws from mixers to extruders

Extruder, number 2

Model: ATLAS EXTRUSION 2020

Production capacity: 175-200-kilogram of corn per hour

Depending on the type of raw materials used, the amount of flavor added, and the density of the bean

Air crystal or itinerary (Conveyor)

Function: transferring the corn chips from the extruder to the oven

The extruder can support up to 50 corn chips

Drying Oven

Three-layer material flow line

Function: Roasting and drying the bean completely and removing moisture from it

Mechanism of work: Equipped with two systems upon request

1- Diesel (diesel) system (Riello) from Italy

2- Gas system (Italian Riello), natural gas or propane

Flavor Mixing Drum

Function: to spread the homogeneous mixture of oil and flavor on the outside of the chips

The spiced is specially made to prevent the flavor from accumulating in one place

2 oil and flavor mixers

Function: mixing the oil with the flavor and spraying it with the pump inside the seasoning

Capacity: 400 liters per tank

Oil pump

Function: To pump the flavor mixed with oil from the mixer and sprinkle it inside the seasoning

Holds quality certificates

ISO9001 – ISO18001-OHSAS18001

And it has the CE certification for European products

For more details, please request a quotation for the product at the bottom of the page